NEWS & INSIGHTS | article

Innovating for impact: Advancing CCUS technologies

Now is the time to make carbon capture, utilisation and storage (CCUS) part of our essential infrastructure.

Recent announcements from the UK government outlined £20bn of funding support to accelerate the essential infrastructure development for widespread CCUS, and two further projects making up the cluster sequencing with Track-2 funding, including the Scottish cluster, Acorn CCS.

In 2021 the Committee for Climate Change identified CCS as an essential component of the ‘balanced pathway’ to meeting the UK’s Net Zero goals. It is a necessity if the UK is to meet its target to deliver 30 million tonnes per annum (equivalent to 12 million cars off the road) of CO2 storage by 2030 and net zero by 2050.

Breaking down carbon capture

Carbon capture and storage is a proven technology with a global capacity of approximately 40MT from industrial CCS projects. Carbon is captured in the form of carbon dioxide (CO2) from industrial emissions, transported from source, and then either used as feedstock for the creation of new products or locked permanently deep underground. CCUS forms a key vector to decarbonise industry areas where emissions are hard to abate, can’t be electrified, or use alternative renewable energy sources. The process of capturing carbon is also a critical enabler for Green Enterprises utilising CO2 as a feedstock, for example, synthetic fuels, and supporting the creation of new industries and jobs.

Scotland, the source of storage

The Acorn CCS project is Scotland’s system for the transport and storage of industrial CO2 emissions using legacy oil and gas infrastructure to carry captured CO2 emissions from the major industrial zones to permanent storage 2.5km deep under the North Sea.

The geology, infrastructure, and proximity of offshore assets to major industrial hubs in the North Sea means the UK is uniquely placed to provide a carbon storage service to both the UK’s industrial and power sectors, boasting an estimated 78Gt of potential CO2 storage offshore the UK. This capacity also allows for imported CO2, placing the UK as a world leader in CO2 storage.

However, the suitability of existing infrastructure, impact of long-term exposure to CO2, and cost of monitoring is a concern.

Tackling the corrosion challenge

During combustion and industrial processes, water is produced alongside the CO2 and other gas impurities which can lead to the formation of carbonic acid.

The acid and impurities pose a huge corrosion risk which can lead to CO2 leaks and pipeline failures. This is forecast to cost the sector £1.7 billion by 2050, and there is concern over the environmental impact of a major CO2 leak.

Accurate qualification of water and other impurities in multi-component CO2 flow is a critical challenge that needs to be solved for the CCS industry to scale. However, if de-risked could result in large cost savings in the build out of transportation and storage networks.

CO2 conformance and containment

A comprehensive measurement, monitoring, and verification (MMV) plan is essential for any proposed CO2 storage site to demonstrate the CO2 is stored safely and that there are no impacts to the surrounding environment. However, the high cost of monitoring long after CO2 injection has stopped will make many potential stores uneconomical. Innovation in this area could reduce the costs of monitoring by up to 50% making long term storage of CO2 economically viable.

Legacy wells are a major risk to safe storage as they potentially provide a leak path to surface for the stored CO2. Current assessment methods only provide a qualitative assessment of their condition based on human judgement. A quantitative approach would allow industry to understand both short and long term leakage risks from wells during operational and post operation phases. This will allow operators to plan injectivity strategies, mmv activities and provide assurance to regulators on the safe and containment of CO2 within the storage complex.

Away from wells, there are a range of technologies available to monitor underground CO2 storage. However, they face reliability, repeatability, and precision challenges. Those that meet the requirements are usually subject to high deployment costs. Therefore to solve this challenge, cost effective and techniques need to be developed and deployed at speed.

Scaling the solution

While CCS is a proven technology, scaling it is a new challenge. Technology development and innovation will help to overcome challenges such as the high costs involved, the impact of impurities in the CO2 stream, and the monitoring of stored CO2.

Through our Open Innovation Programme we are supporting the development of technologies, working with academia, technology start-ups, and tier 1 service companies, that will address these challenges. These include:

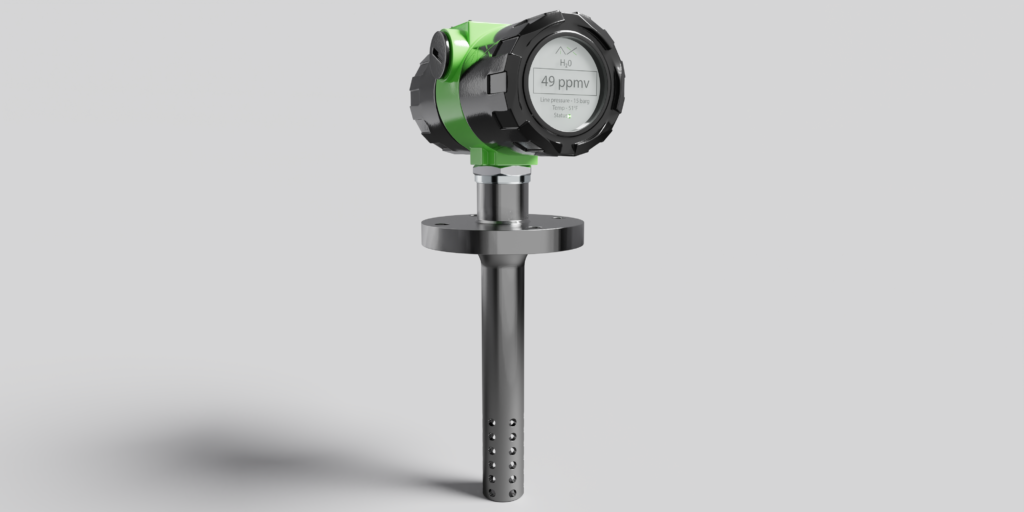

- a first-of-its-kind innovative sensor to accurately measure moisture content in the CO2 stream (AI Exploration)

- a software tool to predict the impact of impurities and corrosion risk to pipelines (Pace CCS)

- an alternative material that is resistant to corrosion and can withstand cold temperatures for piping liquefied cold CO2 for shipping (Enoflex)

- a risk assessment tool providing a quantitative measure, trackable, repeatable and auditable methods of the probability of wells to leak on the injection of CO2 (Heriot Watt University)

- a low cost, permanent, adaptive monitoring system to monitor CO2 plume development using surface deployed distributed acoustic sensing (S-DAS). This idea offers a radical approach to monitoring CCS sites with a move away from 4D seismic monitoring which focuses on full field monitoring to a plume centric and ‘health monitoring’ system (SLB).

The North Sea Transition Authority’s (NSTA) first ever UK CCS licencing round resulted in 21 new CCS licences in depleted oil and gas reservoirs and saline aquifers being awarded, which could potentially store up to 10% of total UK greenhouse gas emissions. It’s emerging technologies, like the ones mentioned above, that will play an important role in developing the build out and safe operation of the new CO2 storage networks.

Unlocking the U

While much of the focus is on storage, we must not forget about the ‘U’ in CCUS. Utilisation of CO2 in the production of chemicals, building materials, surfactants, synthetic fuels could provide an outlet for captured CO2 while storage sites are brought online creating new industries and jobs.

At NZTC we’re progressing the development of utilisation technology, leveraging work we’ve done on alternative fuels, energy hubs and hydrogen production. We’re building strategic partnerships and consortiums to deliver strategic projects and connecting industrial emitters who lie outside of the main industrial clusters. We want to develop Offshore UK as a pan European CO2 storage hub, looking at common infrastructure, transportation options, route optimisation, landing points and infrastructure requirements.

It is a really exciting time for CCUS and the UK can undoubtedly position itself as a global leader, delivering decarbonisation at scale without deindustrialisation, creating a sustainable and cleaner future.

Are you developing a CCS project or technology? NZTC is your technology innovation partner that catalyses breakthroughs, accelerates deployment, ands ensures your success in shaping a greener, more sustainable future.

Subscribe for the latest updates