WAAM-Additive Manufacturing

Project Summary

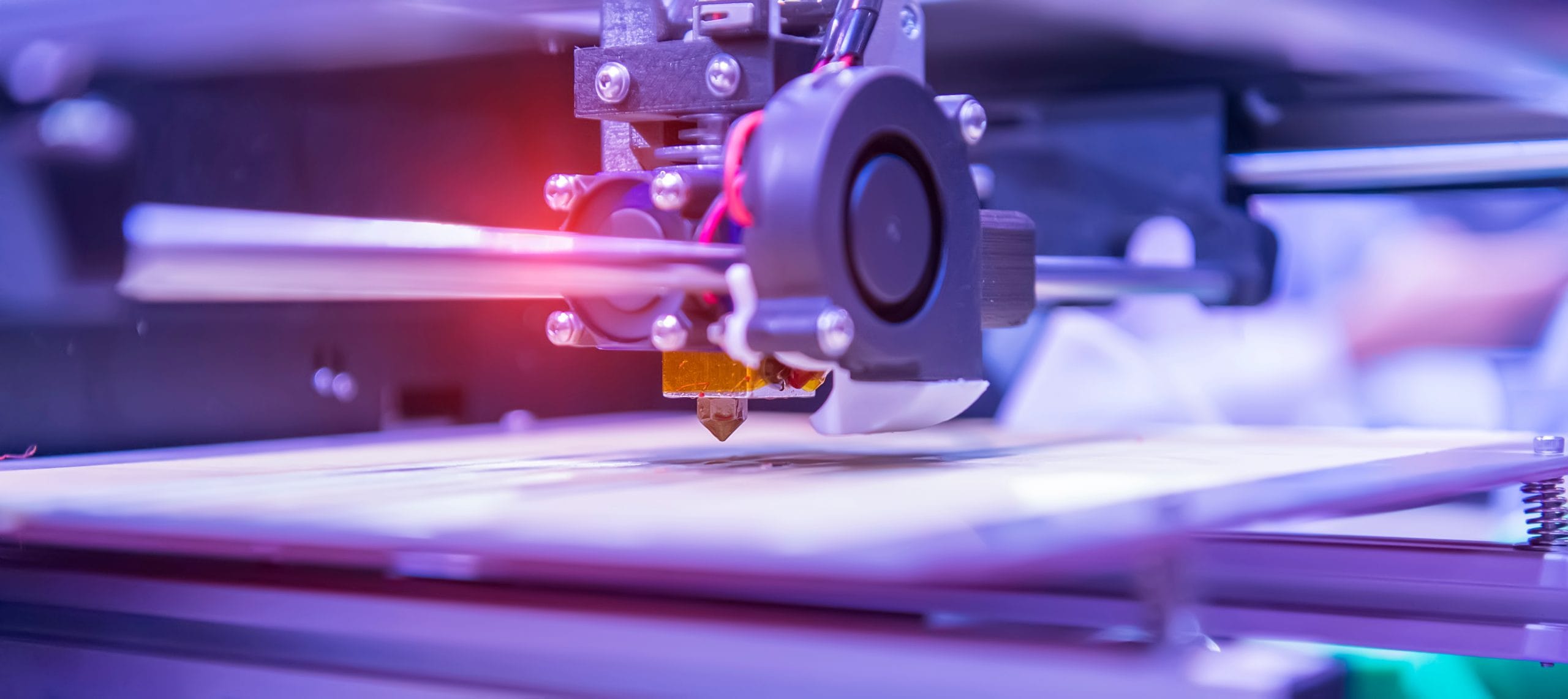

Wire and Arc Additive Manufacturing (WAAM) is a relatively new form of additive manufacturing. Similar to the 3D printing process used for plastics, it uses gas metal arc welding to deposit material layer by layer forming the required shape. This project aims prove WAAM’s capability by creating the first WAAM produced component for offshore use in rotating equipment & build confidence in the technology in the oil and gas industry.

OUTCOMES

The use of additive manufacturing, or 3D printing, is gradually increasing in the energy industry. Currently accounting for less than 0.1% of the overall global manufacturing market, which is currently valued at $12.7 trillion, it is estimated that the 3D printing market will be worth $32bn by 2025, according to the “3D Printing in Oil & Gas – Thematic Research”.

3D printing has emerged as one of the key enabling technologies in driving industrial productivity. 3D printing technology has become prominent in different industries and has significantly influenced automotive and aerospace manufacturing. In the energy industry, some of the technology’s applications include manufacturing spare parts on site, testing new product designs and simplifying inventory management to save costs.

3D printing technology can address the issue of high inventory costs by enabling companies to manufacture parts on a as needed basis. This will result in a reduction in the overall costs spent on supply chain management by using 3D printing as a mainstream manufacturing technology, which would help them to enhance operational efficiency and foster growth.

Let's work together

"Required" indicates required fields