New technologies examined for non-destructive testing (NDT) of composite wraps

Project Summary

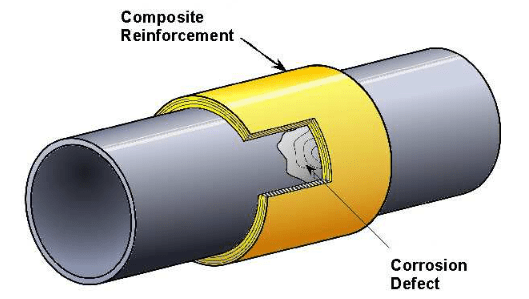

The offshore oil and gas industry requires an inspection technique that accurately determines the condition of pipe surfaces under composite bandages/ engineered temporary wraps.

This study, supported by NZTC, used the current preferred inspection method – Pulsed Eddy Current (PEC) – as a baseline to compare the performance and suitability of two emerging technologies:

- Capacitive Sensing (CS), and

- Low Frequency UT (LFUT).

The aim was to progress a new technology solution to inspect component integrity under manually applied composite bandages/ engineered temporary wraps. This required both a trial of current ultrasonic inspection techniques to explore the potential of ultrasound operating through this material and a feasibility study of capacitive imaging as a potential alternative.

Industry value:

If proven, these inspection technologies could be used to determine more accurately the surface condition and remaining wall thickness of the component underneath the composite bandage without the need for removal.

Key results:

The study focussed on assessing which technologies could inspect through composite wraps, comprising of a combination of analytical support for existing inspection technology and feasibility studies into two alternative approaches: Capacitive Sensing (CS) and Low Frequency Ultrasonics (LFUT) with Coded Excitation. The outcomes of the study were:

- Capacitive Sensing (CS) demonstrated excellent potential in controlled laboratory experiments.

- Low Frequency UT (LFUT) did not produce the resolution or sensitivity required for a practical NDT technique.

Lessons learned:

If this project were to progress further the next steps for each of the technologies would be as follows:

Capacitive Sensing (CS):

- Develop techniques for separating effects on the capacitive response due to metal loss from the effects of varying coating thickness.

- Investigate possibility of AC excitation / pulsed capacitive sensing for evaluation of internal corrosion.

Low Frequency UT (LFUT) with Coded Excitation:

- A more detailed material characterisation programme to produce more accurate sound velocities.

- Improving transducer alignment with respect to the fibre orientation in the composite wrap material.

- Considering the application of alternative coded excitation schemes.

Let's work together

"Required" indicates required fields