NEWS & INSIGHTS | article

Accelerating the Wind Industry: Shape-changing blades

TechX Pioneer Spotlight: Brayfoil Technologies

Switching on 93.6GW in new global capacity in 2021, the wind industry had its second-best year ever, but installations still must quadruple by the end of the decade for the sector to contribute to the world reaching a 1.5℃ pathway and net zero by mid-century, according to the Global Wind Energy Council. For the wind industry, this means more turbines and new, advanced technologies to produce more power from the same device.

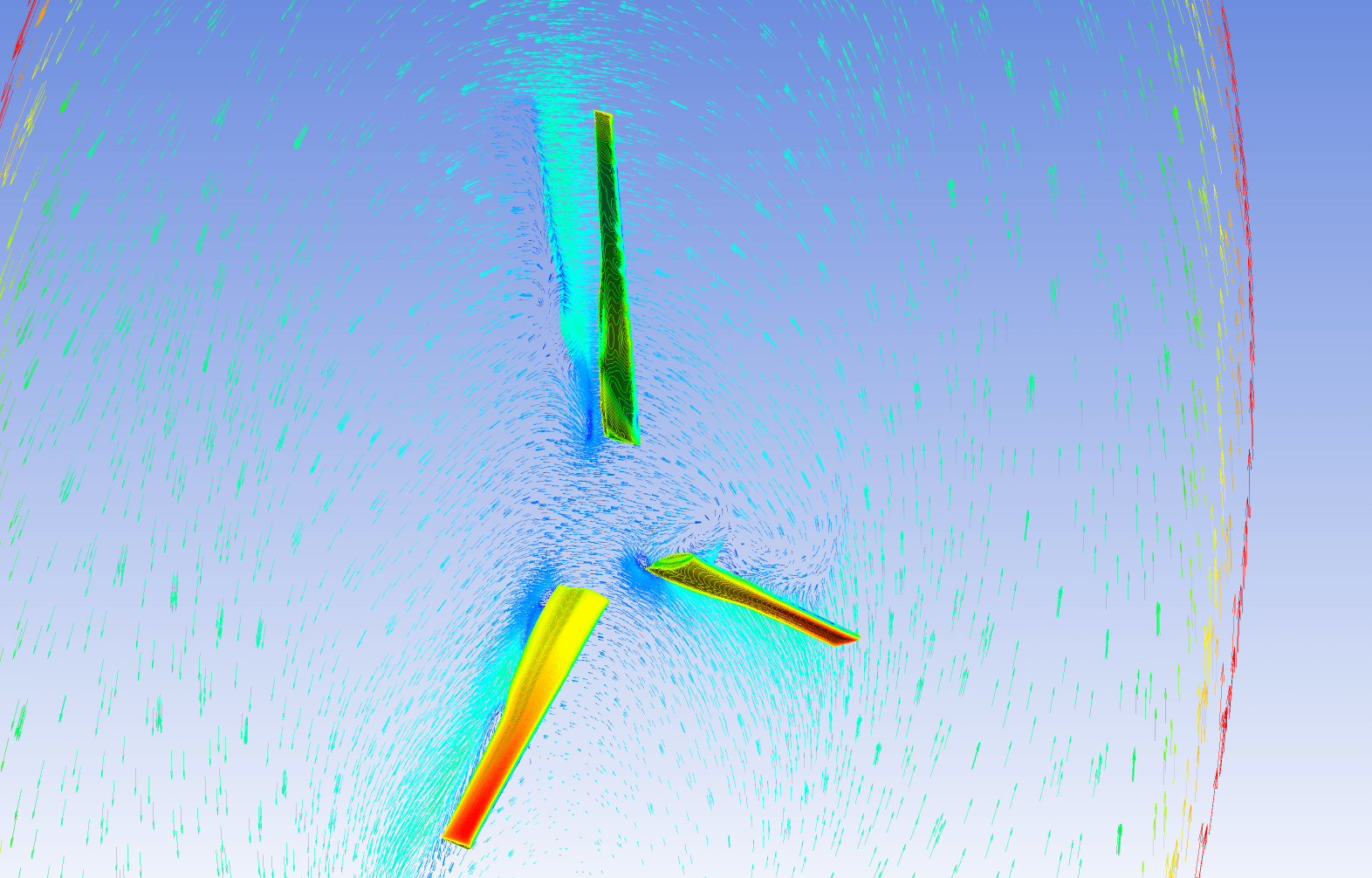

Brayfoil Technologies’ offering does just that. Founded by Matthew and his father Robert Bray, the start-up is developing a biomimetic shape-changing blade that can reduce excess loadings in gusts and storm conditions, thereby enabling larger and more efficient turbines. The blade acts like an aircraft wing’s flaps and ailerons but without the complexity; it has an intrinsic lifting shape which can actively change using an internal actuator to vary the lift and drag and thereby reduce loadings. As the shape changes, the blade’s angle also shifts relative to the incoming wind for faster adaptation to changing conditions.

A first for the industry, Brayfoil’s manufacturing materials are commercially viable and simple, allowing for typical blade length to be extended by approximately 13% and potentially increasing annual power output by 25%. The technology, which is globally patented, has the potential to reduce the cost of wind energy by 20% if executed along the entire blade.

Leading a strong team comprised of experienced aeronautical engineers and skilled composite artisans, CEO Matthew Bray is passionate about shaping and modernising the future of the wind industry to help accelerate sustainable energy.

“Research done by Oxford University in 2009 mapped the shape of a bird’s wing in flight, which further inspired us to rethink how blades and wings can work, to create biomimetic adaptive structures that change shape, just like a bird’s wing.

“The wind industry at present is very resource intensive – our aim is to allow wind turbines to last longer through our unique technology. We also use materials that are circular by design, incorporating recyclability into all our composites.”

With the company based in South Africa, Brayfoil Technologies are keen to utilise TechX’s global network to get closer to potential customers and develop a full understanding of the wind ecosystem. To date, the company has built a number of prototypes and plan to launch their first pilot turbine later this year with 7.5 metre blades and a height of 25 metres.

You can follow Brayfoil Technologies and the rest of our latest TechX cohort’s journey via our social media channels, or by subscribing to our newsletter.

Subscribe for the latest updates