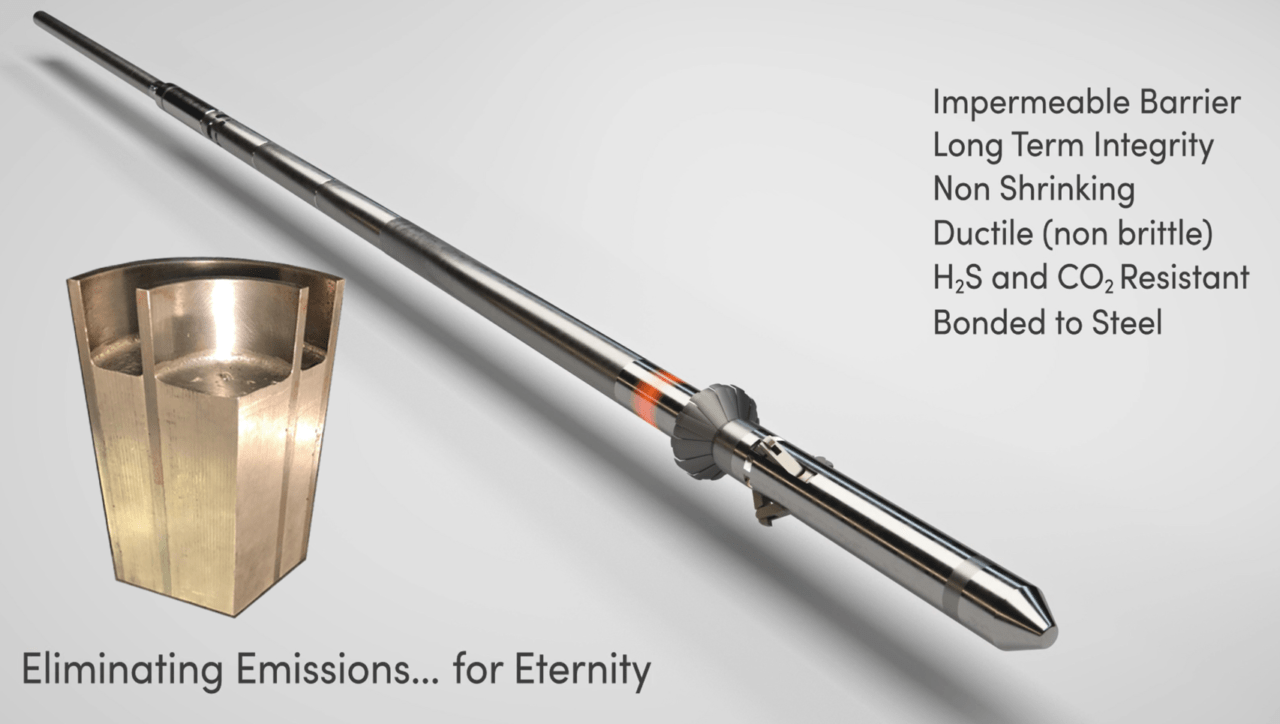

Fusion Barrier

Project Summary

isol8’s vision is to set the new global standard in zero emission wellbore isolation products to maximise client value and radically reduce costs. Their Fusion P&A product aims provide greater long term integrity assurance than 50m of cement. isol8 is undertaking a rigorous qualification testing programme based on the ISO-14310 standard to demonstrate the quality of their unique bonded-alloy barriers.

In April 2022, Isol8 invested more than £150,000 in a new manufacturing facility to produce its thermite modules, housed within its Aberdeen headquarters, as it scales up to meet international demand.

The company is now looking to scale up to address “significant international demand” for the technology. The company increased its headcount by 30%, and it expects to recruit a further 20-30 staff over the next 12-24 months.

OUTCOMES

Their operating company partners estimate the cost savings from a successful one-time deployment of the technology is between £1.5m for a platform well and £7m for a subsea well. If the technology is successfully developed, the estimated cost saving in the UKCS is between £2billion & £5billion.

Let's work together

"Required" indicates required fields