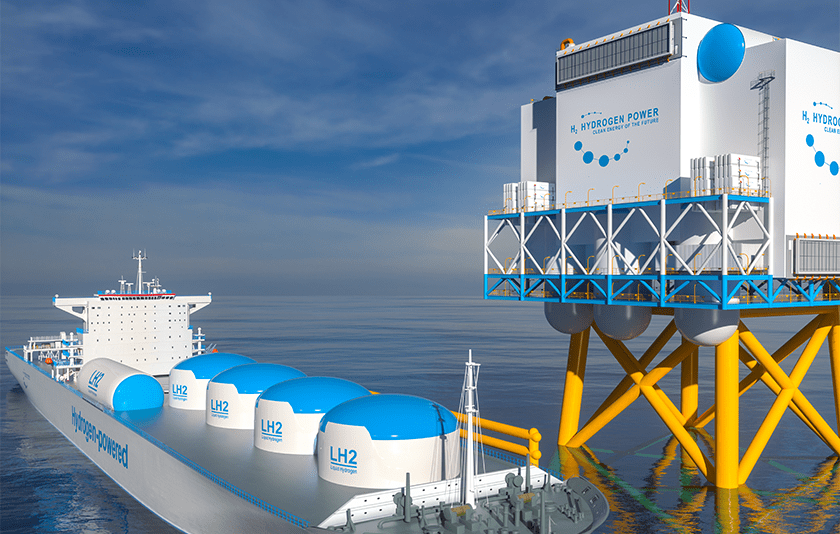

The Hydrogen Offshore Production (HOP2) project overview

HOP2 is funded by the Scottish Government’s Just Transition Fund with the aim of anchoring the hydrogen production sector in Scotland and creating a positive impact on jobs, skills, education and decarbonisation across Scotland and in the North-East and Moray specifically.

The UK is at a pivotal moment in its energy transition journey. The North Sea offers some of the world’s richest offshore wind resources, yet much of this potential remains out of reach – stranded far from shore, beyond the easy integration into the electricity grid. This is more than a technical challenge; it’s a question of how we ensure that the UK’s natural assets deliver real, lasting benefits for our communities, our workforce, and our climate ambitions.

The challenge is clear: how do we unlock these remote wind resources and turn them into a force for good, not just for the energy sector, but for the people of Scotland—especially those in the North-East and Moray, where the legacy of oil and gas is both an opportunity and a responsibility.

The HOP2 project seeks to demonstrate whether offshore hydrogen production is technically feasible at a scale of 500MW to 1GW through strategic repurposing of existing UKCS assets, or if new build assets provide the optimal route.

The North Sea Transition Authority’s decommissioning strategy (May 2021) highlights the sheer scale of these assets; over 320 fixed platforms, 250 subsea systems, 20,000km of pipelines, and around 7,800 wells currently in the United Kingdom Continental Shelf. It is imperative that, before decommissioning, a comprehensive assessment is undertaken to identify all possible alternative uses for these assets.

Through this innovative re-use of existing North Sea infrastructure, HOP2 is not just addressing the technical challenge of stranded wind resources but also supports a Just Transition for the offshore energy workforce, ensuring their expertise remains valuable in the evolving energy landscape.

The HOP2 project is being delivered across three distinct phases, each addressing a critical aspect of offshore hydrogen production:

Phase 1 focused on identifying which existing assets could be repurposed for hydrogen production, laying the groundwork for a new offshore hydrogen sector.

Read more.

Phase 2 is about defining the technical concept in detail, working with technology vendors and engineering partners to design a system that is efficient, safe, and ready for the harsh realities of the North Sea. Read more.

Phase 3 will look further ahead, exploring what could be possible as technology and markets evolve, and setting out a vision for offshore hydrogen production that maximises benefits for Scotland’s people and supply chains. Read more.

Key findings

Phase 1: Phase 1 found that is it technically feasible to repurpose existing substructures for 500MW Offshore Hydrogen production.

Phase 2: Phase 2 of the project produced a topsides design that makes efficient use of space, weight, and balance of plant for offshore hydrogen production by converting an existing offshore platform. Through phase 2 it became evident that existing electrolysers are not suited for the harsh environments of the North Sea therefore further work is required to qualify existing technology.

The HOP2 project is ongoing and will conclude in April 2026.

Phase 1 Overview

Phase 1 of the project delivered a Basis of Study and Concept Development to assess the technical, economic, regulatory, and logistical viability of repurposing existing oil and gas assets in the UK Continental Shelf (UKCS) for hydrogen production, with a view to deployment in the early 2030s.

The scope included assessment of repurposing platforms and pipeline systems, the selection of key production and processing systems and undertook an assessment of regulatory gaps. A summary of the Phase 1 activity is provided in this section.

Full reports for Phase 1 can be found here and here.

Repurposing Opportunity

Activity Overview: The project assessed the potential for repurposing existing North Sea oil and gas infrastructure for offshore hydrogen production, analysing over 320 fixed installations and extensive pipeline networks completing comparative analysis to identify the top candidates for both platform and pipeline repurposing.

Key Findings: Twelve existing UKCS offshore assets and three pipelines were identified as technically suitable for repurposing into hydrogen production facilities. The assessment demonstrated that strategic repurposing of existing assets for a 500MW scale project is technically feasible when considering utilising platform substructures and existing pipeline networks.

The analysis concluded that while topsides repurposing/retrofitting is not feasible due to production scale requirements, the substructure and pipeline infrastructure presents significant opportunities.

The Scottish supply chain is already well-positioned to support repurposing activities, with established ports, marine operations capabilities, and existing experience in offshore decommissioning that can be leveraged for repurposing projects.

Four concept options were developed: repurposing single large assets (Option 1A), creating hydrogen production clusters from multiple assets (Option 1B), repurposing asset complexes with bridge-linked platforms (Option 1C), and new-build facilities (Option 2).

Recommendations: Pipeline repurposing analysis identified eight existing pipelines as potential candidates, with the Fulmar pipeline emerging as the most suitable for hydrogen transportation due to its favorable cessation of production date and proximity to identified assets. Future developments should prioritize engaging with existing asset owners and conducting detailed technical assessments of structural integrity.

Production Technology Assessment

Activity Overview: Comprehensive evaluation of hydrogen production technologies for offshore hydrogen production. This included an assessment of eight different electrolysis technologies and balance of plant requirements.

Key Findings: PEM (Proton Exchange Membrane) electrolysis was selected as the preferred technology for offshore application. PEM demonstrated superior performance due to its compact footprint (approximately one-third the volume and weight of alkaline systems), higher operational flexibility for variable wind resources, and simplified balance of plant requirements.

For balance of plant systems, thermal desalination was selected for seawater treatment to utilize waste heat from electrolysis, indirect seawater cooling for process cooling to minimise corrosion issues, and reciprocating compressors for hydrogen compression to handle variable load cases.

The technology assessment revealed that current electrolyser configurations are not optimised for marine environments where space constraints are more critical than onshore applications.

Recommendations: Technology development efforts should focus on larger stack sizes and marine-optimised designs to reduce equipment quantity and improve space efficiency. Vendor engagement is critical to advance technology readiness for harsh offshore environments, particularly addressing equipment survivability in saliferous conditions.

Transport and Storage

Activity Overview: Assessment of hydrogen transportation methods, market analysis, and storage solutions for offshore-produced hydrogen, including evaluation of ship-based and pipeline transport options.

Key Findings: Gaseous pipeline transportation was identified as the preferred method over ship-based and alternative vector options. The Hydrogen Backbone Link (HBL) presents the primary export route, with potential for new-build pipelines to tie into this network.

For storage solutions, geological options including salt caverns and depleted oil and gas reservoirs were identified as most suitable for large-scale interseasonal storage. Pipeline line packing could provide 2-3 days of production capacity buffering using existing large-diameter pipeline infrastructure. The UKCS is estimated to have between 2660-3450TWh of potential hydrogen storage capacity in depleted reservoirs.

Recommendations: Detailed transport and storage solutions should be developed following specific production site selection.

Topsides Layout and Design

Activity Overview: Development of facility layouts for four concept options, incorporating safety philosophy, equipment arrangement, and weight/space optimization for offshore hydrogen production.

Key Findings: The layout study produced viable designs for all concept options, with particular success for Option 1A (single large asset repurposing using Ninian Central Platform) and Option 2 (new-build hybrid solution).

Critical design challenges include limited space availability on repurposed platforms requiring optimized layouts and potential advancement in electrolyser technology. The study established that centralized production offers significant advantages through system-level management strategies and economies of scale, including centralized seawater lift, desalination, electrolysis, and cooling systems.

Recommendations: Option 1 was carried forward for further study in Phase 2 Concept Definition. Future phases should focus on detailed structural assessments of existing platforms, particularly caisson integrity and conductor guide frames.

Economics

Activity Overview: High-level economic assessment determining levelized cost of hydrogen (LCOH) for offshore production scenarios and comparison with onshore alternatives.

Key Findings: The cost of electricity dominates offshore hydrogen production economics, accounting for approximately 50% of LCOH compared to 70% for onshore production. CAPEX and DEVEX contribute 35% to offshore LCOH, presenting opportunities for cost reduction through asset repurposing (up to 15% CAPEX reduction) and economies of scale.

Offshore hydrogen production costs exceed onshore alternatives due to the additional complexity of offshore execution. However, the analysis identified that non-economic factors could offset these cost differences, including socio-economic benefits, reduced decommissioning costs, and lower environmental impact. Combined improvements in electrolyser efficiency with material electricity cost reductions present the most significant opportunity for LCOH reduction.

Recommendations: Offshore hydrogen production is most likely to be unlocked by non-economic factors including onshore water scarcity, competing land use priorities, and electrical grid constraints.

Regulatory Landscape

Activity Overview: Comprehensive review of UK regulatory framework for offshore hydrogen production, including environmental and safety regulations, with comparative analysis of international approaches.

Key Findings: The regulatory framework for offshore hydrogen production in the UK is still evolving. While recent updates have addressed hydrogen transportation and storage, gaps remain in legislation covering offshore production, environmental consenting, and power cable installation.

Safety regulations are largely applicable, with offshore hydrogen facilities falling under existing frameworks such as the Offshore Safety Case Regulations (OSCR), Pipeline Safety Regulations (PSR), and others. However, there is a need for streamlined and hydrogen-specific regulations to support future development.

International comparisons, particularly with Australia and EU countries, show similar challenges with Australia taking proactive steps to create a consistent national regulatory framework for hydrogen.

Recommendations: Engagement with NSTA is essential to clarify storage licensing requirements and consenting pathways. The development of hydrogen-specific regulations would provide greater certainty than continued adaptation of existing frameworks.

Conclusions and Next Steps

Based on the findings of Phase 1, Phase 2 of HOP2 was refined to focus on Concept Definition through vendor engagement and detailed engineering development.

The project acknowledges that the initial 2030s deployment target may be overly ambitious, requiring revised timeframes based on updated wind and hydrogen production projections.

With delays in deployment of offshore wind resources and hydrogen production projects, the shifting of timeframes also allows the HOP2 project to take a wider look at the offshore hydrogen production opportunity, and consider what this may look like towards 2050. This will be further addressed in Phase 3.

Phase 2 Overview

Phase 2 of the HOP2 project focused on Concept Definition, building directly on the findings and recommendations established during the Phase 1 Concept Development stage.

This included vendor engagement activity followed by a concept definition study with the ultimate aim of integrating the system design with electrolysers, optimising the design for space, weight, overall system efficiencies, and maximising synergies between unit operations, such as utilizing excess heat from electrolysis processes.

A summary of the Phase 2 activity is provided in this section.

The full Phase 2 summary report will be published in November 2025.

Electrolyser Selection

Activity Overview: Vendor engagement to select a suitable electrolyser technology for offshore integration.

Key Findings: The Bosch ELY1250 PEM stack was chosen for its modularity and suitability for bespoke Balance of Stack (BoS) design. The selection process considered operational requirements such as controlled temperature and humidity, which present integration challenges in offshore environments.

Recommendations: Further work is needed to address the environmental requirements for PEM stacks in offshore settings, particularly marinisation and integration into topsides design.

Balance of Stack (BoS) and Balance of Plant (BoP)

Activity Overview: VWS Westgarth (Veolia) developed bespoke BoS and BoP systems optimised for footprint/weight minimisation, energy efficiency, and operability through consolidation and economies of scale. BoS encompasses gas/liquid separation, anode water treatment, and electrolyser cooling, while BoP includes water treatment and hydrogen purification.

Key Findings:

Balance of Stack: Veolia developed a custom BoS design integrated with proprietary BoP technology to optimize footprint, energy efficiency, and operability. The design achieved significant consolidation with 12 x 41.5MW arrays (versus 50 x 10MW in Phase 1), each supporting 33 x 1.25MW Bosch stacks across two elevations. One Phase 2 array fits within the footprint previously required for three Phase 1 arrays, achieving nearly 12MW additional capacity with no real estate increase.

Water Treatment Technology: Thermal Multi-Effect Distillation (MED) was selected over Seawater Reverse Osmosis (SWRO) for desalination due to better energy efficiency, lower chemical use, smaller footprint, and operational simplicity. Electrodeionisation (EDI) units provide final water polishing to ultra-pure standards.

Gas Purification: Hydrogen purification involves deoxygenation reactors to reduce oxygen to below 10 ppmv and silica gel dryers to remove residual water vapor, ensuring hydrogen meets pipeline specifications. Equipment includes deoxygenation reactors, dryer vessels, and regeneration gas compressors.

Overall: Consolidation significantly improves space/weight efficiency versus modular arrays and MED technology is optimal for offshore due to waste heat integration. Bespoke large-scale arrays designed for offshore deployment are strongly preferred over adapted standard modular units.

Recommendations: Continue to optimise the design for space, weight, and energy efficiency when the concept gets taken forward through subsequent design phases.

Primary Electrical Systems

Activity Overview: Design and integration of the electrical system to interface with offshore wind power and supply the electrolysers.

Key Findings: Petrofac developed the system architecture, including transformers, switchgear, shunt reactors, and rectifiers (thyristor and hybrid types). The system includes 275/66/66 kV transformers, gas-insulated switchgear, shunt reactors, and subsea cable reception.

The system matches hydrogen production load to wind farm output using forecasting and load management. Simulations addressed load flow, short circuit, and harmonics, with a 540MW wind farm assumed to match hydrogen production needs.

Recommendations: Future design phases should include a review of reactive power compensation and consider energy storage options like batteries and subsurface hydrogen.

Concept Definition: Topsides Integration

Activity Overview: Integration of all systems into a coherent topsides design and optimisation for offshore deployment. Apollo Engineering led the integration of electrolyser arrays, BoS, BoP, and primary electrical systems into a coherent topsides design.

Key Findings:

Layout: The revised design consolidated the electrolyser arrays over three deck levels instead of four, maintaining hazard zoning and optimizing layouts for safety and operational efficiency. The design includes seawater cooling, water treatment, hydrogen compression, flaring, HVAC systems for electrical equipment cooling, and secondary electrical systems for platform operation.

Structural Design and Weight Estimation: The topsides structural framing was adapted to the larger electrolyser arrays and primary electrical systems, with new interface steelwork designed to maintain existing load paths to the Gravity Base Structure (GBS). Weight estimates indicate a dry weight of approximately 31,600 tonnes, within the limits of the existing substructure but representing an engineering challenge for installation. Installation concepts include integrated deck lifts using heavy lift vessels or modular installation.

Technical Safety and Environmental Considerations High-level safety studies assessed hydrogen leak scenarios, gas dispersion, explosion, and jet fire risks. The relatively low hydrogen inventory and rapid shutdown capabilities suggest low fire escalation risks, though further explosion risk assessment is recommended. Environmental impacts include seabed disturbance, discharges to sea, and emissions, with repurposing expected to reduce impacts compared to historic oil and gas use.

Recommendations: Maintain focus on safety, particularly regarding hydrogen leak and explosion risks as the concept progresses through design phases. Further assessment of explosion risk around electrolyser arrays is advised. Environmental permits and detailed assessments will be required as the project progresses. Engage with installation contractors early to confirm feasibility of heavy lift or modular installation approaches.

Cost Estimation

Activity Overview: Development of a Class 4 (+50% / – 30%) cost estimate for the facility.

Key Findings: The total CAPEX is projected at approximately £1.56 billion, covering electrolysis stacks, BoS/BoP, primary electrical systems, topsides integration, and client costs with contingency. This excludes the offshore wind farm, substation, and subsea cables.

Recommendations: Continue to refine cost estimates as engineering definition improves.

Conclusions and Next Steps

Phase 2 of the project produced a topsides design that makes efficient use of space, weight, and plant balance for offshore hydrogen production by converting an existing offshore platform. The engineering detail developed are thorough enough to give a clear picture of the potential for hydrogen production in this scenario.

However, it is advised not to pursue further conceptual design work at this stage, as it would not be cost-effective until a potential owner, operator, or developer is found to take the concept forward. Considering how the hydrogen market is expected to develop, it’s likely that offshore hydrogen development will only begin once the onshore market is more established.

Given this, and the general parallel deceleration of the offshore wind sector build out, Phase 3 will pivot to focus on what could be possible for offshore hydrogen production in the future. It will incorporate “the art of the possible” and focus on a future vision for offshore hydrogen production, maximising use of digital technologies and emerging electrolysis technologies that would be well suited to the offshore environment.

Phase 3 Overview

Objective: Development of a ‘conceptual design’, incorporating the art of the possible for offshore hydrogen production.

This includes acceleration of seawater electrolysis, addressing key technical challenges that arose during Phases 1 and 2 and delivering a different vision for offshore hydrogen production to maximise benefit to Scottish and UK supply chains.

Scope overviews – all currently ongoing

Scope 1: Latent Drive

- Support advancement of a sea water electrolyser.

- Development of bipolar membranes and bipolar plates suitable for direct seawater electrolysis and offshore-scale SeaStack systems.

Scope 2: Marinisation- Abbeymeade

- Electrolyser Marinisation TQP suitable for the deployment of electrolyser technology in harsh maritime environments with suitable PRAMS (Performance, Reliability, Availability, Maintainability and Security) criteria to sustain autonomous operations for periods of not less than 10 months with maximum uptime availability within that 10 months with limited intervention other than remotely, including the potential use of robotics.

- To act as a foundation toward development of a potential standard that can be used across industry for the qualification of electrolysers for a marine environment.

Scope 3- Environmental -Apollo

- Provide a comprehensive understanding of expected and potential environmental impacts from normal operations and worst-case scenarios along with consideration for the commissioning and decommissioning phases.

- Identification of Unplanned Release Scenarios

- Assessment of Environmental Implications

- Evaluation of mitigation and emergency procedures

- Recommendation for further analysis or controls

- Dispersion modelling

Scope 4: Digital Design – MES

Deliver an ‘Art of the possible’ concept definition study for 1045, envisioning an offshore hydrogen production facility designed from the ground up with digital technologies and methodologies.

- Integration of automation, robotics, artificial intelligence, machine learning, digital twins and remote operations ensuring concept is:

- Technically feasible – addressing known engineering, safety, and operational challenges.

- Digitally optimised – enabling autonomous operation with minimal human intervention

- Future ready – incorporating projected advances in digital and hydrogen technologies to define clear pathways for qualification and deployment.

Scope 5: Economic – Apollo

What is needed to make offshore hydrogen production economically and technically attractive?

- Policy and Regulatory Frameworks – evaluate policy levers needed for offshore hydrogen to gain parity with onshore.

- Cost drivers and incentives.

- Societal benefits and strategic value of offshore hydrogen

- Long term market potential and market prioritisation tool including alternative fuel production and storage requirements

Related

Let's work together

"Required" indicates required fields